Field-Joint Coating Materials

Fusion Bonded Epoxy (FBE)

Fusion Bonded Epoxy (FBE) coating has excellent mechanical properties, corrosion resistance and durability. It is widely used on oil and gas pipelines for its long-term, low-maintenance, reliable operational value.

FBE Layering

Single Layer FBE

FBE can be applied as a single layer or base coat primer to welded field joints. FBE coatings provide adequate corrosion resistance for pipelines installed under harsh conditions in deep waters, through rolling plains, rocky mountainous areas, in the desert, and the artic.

Dual Layer FBE

Dual-layered FBE coatings offer mechanical damage resistance from impact or gouging during handling and construction activities. It also provides anti-corrosion and cathodic disbondment-resistant properties of the first layer.

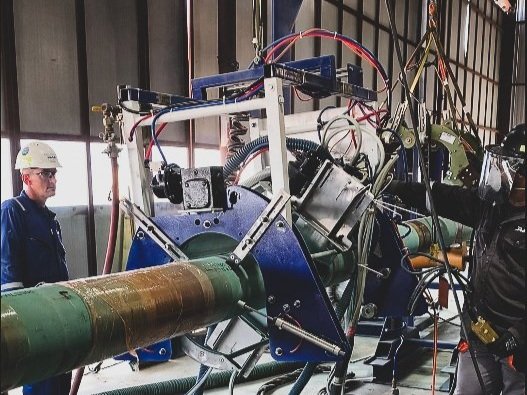

FBE Equipment

RAE’s Powder Coating machines automate the FBE coating processes by accurately aligning the field joint within the target coating area, then evenly applying the FBE coating via electrostatic spray guns that spray side-to-side and rotationally around the pipe.